For drinking water utilities, the unprecedented drought in 2022 has resulted in an increased need to determine and develop alternative sources of potable water. In some cases, such utilities are turning to groundwater that has been compromised by natural or man-made contaminants. For such situations, Envirogen provides treatment solutions for a variety of contaminants utilizing both ion exchange and/or biological systems to treat new sources of groundwater or to return contaminated sources into service. Through either direct consultation with the water utilities or the engineering firms tasked to provide the overall plant design, Envirogen can provide the design, fabrication, installation, commissioning, and service to these IX and biotreatment systems.

Common contaminants treated by Envirogen include:

- Arsenic

- Chromium (including hexavalent chromium)

- Nitrate

- Perchlorate

- Radium

- Uranium

- Organics

New Hexavalent Chromium Standard is Arriving Soon

With the State of California projecting to promulgate a new MCL requirement for hexavalent chromium in 2023, Envirogen has multiple cost-effective solutions to treat this contaminant to potable water requirements. Both the regenerable ion exchange and bioreactor-based technologies, outlined below, have been utilized by clients to treat metals such as hexavalent chromium.

Ask us how you can be prepared to effectively treat this metal when this new MCL becomes effective.

Staggered-Bed Regenerable Ion Exchange

Envirogen employs proprietary, high-performance regenerable ion exchange systems (IX), the SimPack™ and MinX™ technology, which each provide superior treatment efficiency and process flexibility with minimal waste rates and low operating costs.

SimPack IX Technology:

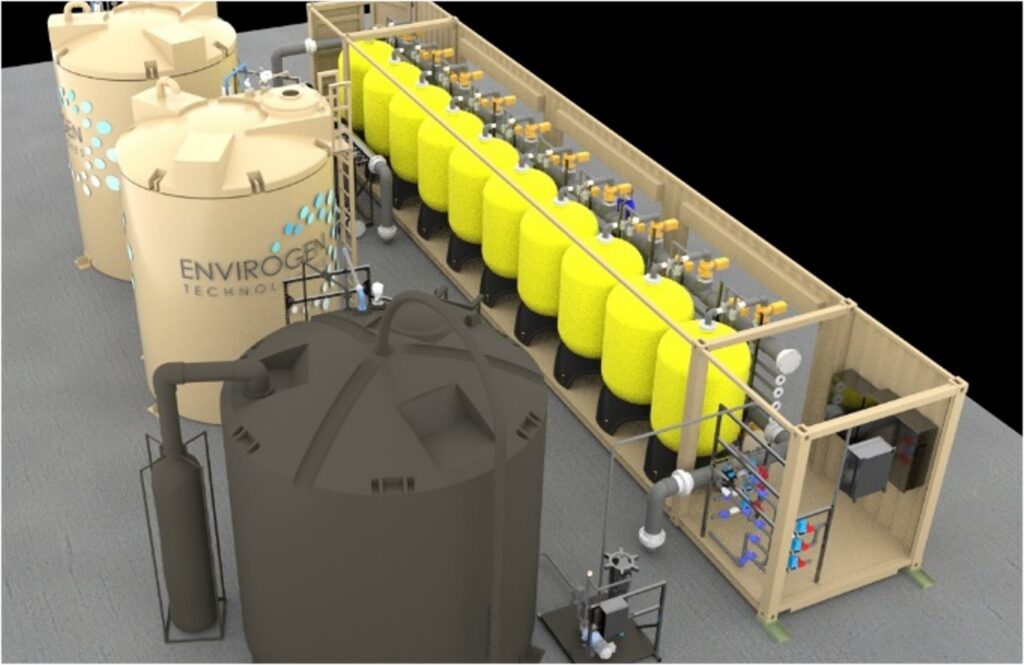

Used for larger utilities and water districts to treat contaminated water at flowrates from 400-3000 gpm. The technology uses a multi-bed design operated in a staggered mode process, employing specialty resins for the particular target contaminants. The staggered bed is an N+3 design which means that all but three of the vessels are online providing treatment while two vessels are being regenerated and one vessel is in standby. This design provides the system treatment redundancy that is required by the California Water Resources Board (CWRB)-Division of Drinking Water, while producing a consistent effluent water quality that meets the target water quality requirements. The SimPack technology can be designed and installed in a shipping container and delivered directly to site, or if the client prefers, can be installed on site in a building.

Click play on the animation to see a fly-by of the containerized version of the SimPack system, including the salt/briner tank, two waste tanks, prefiltration, and ten (10) IX vessels inside the container:

MinX Technology:

MinX technology is utilized for smaller water communities requiring treatment at flowrates of 400 gpm or less. It uses the same technology principles as the SimPack design, but with an N+1 method such that three vessels with specialty resin are online providing treatment at a time.

MinX Installation Examples:

Biological Treatment – Fluidized Bed Bioreactor

Envirogen’s experience extends to designing and installing the first biological treatment system in the United States for the treatment of nitrate – and perchlorate-laden groundwater destined for drinking water use. The plant, located in Rialto, CA, utilizes Envirogen’s Fluidized Bed Bioreactor (FBR) technology to effectively biologically reduce the incoming levels of nitrate and perchlorate to meet the regulatory maximum contaminant level (MCL) requirements.

FBR Technology Installation Examples:

Continue to contact:

New Hexavalent Chromium Standards come into effect in 2023. Contact us now to find out how you can get prepared to meet the new MCL requirement.