Envirogen treatment solutions for selenium for legacy wastewater, CCR leachate and ash pond contact water

There are several technologies available for treatment of selenium, including biological reduction, chemical precipitation, ion exchange, reverse osmosis, and zero-valent iron. Water treatment objectives should be cost-optimized over the life cycle of a project, taking both capital and operating costs into consideration. The best treatment option is often dictated by the water chemistry, both the concentration and form(s) of selenium in the water, which can change during various stages of pond closure.

Regulatory Drivers

EPA regulations, including the Effluent Limitations Guidelines for Steam Electric Power Generation (ELG rule), set federal limits on the levels of toxic metals in wastewater that can be discharged from coal-fired power plants. In addition, the Disposal of Coal Combustion Residuals (CCR) from Electric Utilities and Independent Power Producers (CCR rule) discourages additional CCR waste storage in surface ponds and encourages coal facilities to dewater and close the ponds. The EPA is currently reviewing the ELG rule for legacy wastewater and CCR leachate. With growing regulations and local environmental concerns over selenium, it’s essential to select a treatment option for CCR contact water collected during closure that is both efficient and sustainable.

Envirogen’s selenium treatment offering includes:

• Biological processes (Fluidized Bed Reactor)

• Iron-based media (Advanced Metals Removal System; AMRSTM)

• High efficiency ion exchange system (SimPackTM)

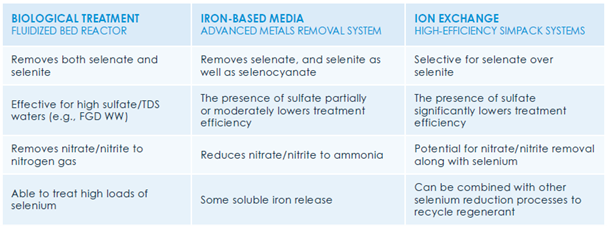

Summary of technologies for treatment of selenium:

Biological Treatment - Fluidized Bed Reactor (FBR)

The Envirogen FBR is a proprietary biological water treatment system deployed to achieve selenium treatment efficiencies of up to 99% using an active, fixed-film bioreactor, that fosters the growth of microorganisms on a hydraulically fluidized bed of fine specified granular activated carbon (GAC) media. Because the GAC particles are small and suspended, they present a large surface area for microbial growth and attachment. The fluidized bed allows for very high attached biomass concentrations and consistent performance under steady-state conditions without backwashing. A growth substrate (e.g., acetic acid) and a phosphorus nutrient are supplied to the FBR, which promotes metabolism by the attached microorganisms of all the dissolved oxygen, nitrate, nitrite, and soluble selenium. As the “living” media bed expands and fluidizes further, the bed reaches a control point where a patented device gently shears excess biofilm from the media surface. The sheared suspended biological and selenium solids are continually discharged with the treated water and are removed after the FBR by filtration. Suitable for a broad range of influent flow rates and selenium concentration levels, our FBR containerized/mobile designs provide low-cost installation. Our treatment systems have been successfully operated at ranges from 50 to 6,000 gpm while simultaneously providing high performance at low capital and operating costs. A flexible and adaptable approach to technology means we can provide additional add-on modules to tackle a range of downstream applications including suspended solids separation and handling.

Envirogen Fluidized Bed Reactor (FBR) – Biological Treatment Process.

Iron Based Media – Advanced Metals Removals System (AMRS)

The Envirogen advanced metals removal system is an active water treatment system that can be utilized as the sole selenium removal treatment option. The media in the AMRS is hydraulically fluidized in a reactor like the FBR process. The mode of fluidization allows for use of multiple iron-based media formulations to achieve up to 50% lower capital cost compared to conventional ZVI system designs. The AMRS is engineered to provide the fluidization flow flexibility needed to utilize varying types and grades of ZVI media formulations regardless of media size and density. Extensive research and testing of various iron-based media available in the market has been completed to understand the performance differences and to allow selection of the optimum zero valent iron media for each application (resulting in the development of Envirogen’s high-efficiency FerroLock ZVI media). Our approach is to recommend pilot and/or lab scale testing to examine the specific characteristics of your wastewater and select the best ZVI media to use from an overall performance, longevity, and life-cycle cost standpoint. Validation studies conducted on legacy wastewater stored in a coal ash pond have demonstrated the performance of the AMRS to remove selenate from 110 ppb down to below 1 ppb.

An Envirogen field-based pilot and full scale AMRS system utilizing FerroLock™ ZVI media.

Ion Exchange – High Efficiency SimPack System

Envirogen’s patented SimPack ion exchange technology is used to treat contaminated water at flowrates up to 2000+ gpm and can remove selenium to low levels depending on the water chemistry and selenium species. The technology uses a multi-bed design operated in a staggered mode process, employing specialty resins for the particular target contaminants. The staggered bed is an N+3 design which means that all but three of the vessels are online providing treatment while two vessels are being regenerated and one vessel is in standby. The regeneration system is controlled and monitored by a Programmable Logic Controller (PLC) – utilizing Envirogen SimPack control logic to minimize waste rates and salt consumption. The SimPack technology can be designed and installed in a building, or in an engineered shipping container and delivered directly to the site to shelter the system from weather and tampering. In addition, this technology has the advantage of a small footprint and automated operation, making it ideal for space-restricted treatment facilities and remote locations.

Envirogen Ion Exchange / High-Efficiency SimPack System.

Envirogen Life Cycle Cost Assurance Programs

For ongoing peace of mind, our systems are backed by a performance guarantee over the lifetime of the installation, creating the best opportunity for an optimized life-cycle cost. This manages the risk of non-compliance and allows clients to focus on their core business.

Envirogen has over 20 years of turnkey design, installation, and operations and maintenance (O&M) experience with dewatering and groundwater turn-key remediation projects at more than 100 sites. Our integrated O&M offering includes engineering, process, treatability, and other technical services as important components. This commitment of technical expertise in support of O&M allows us to be flexible to adapt to changing conditions for maximum reliability.