Comprehensive Wastewater Solutions

With increasing population and industrial activity, higher levels of treatment are essential before discharging both municipal and industrial wastewater. The United Nations Sustainable Development Goals (UN SDGs) have set clear targets for improving water quality, promoting integrated water resource management, enhancing water use efficiency, and restoring water-related ecosystems.

Envirogen is an expert in providing specialist wastewater solutions. With a commitment to excellence and environmental sustainability, our team delivers tailored solutions to address even the most complex water and wastewater challenges, including:

- Organics and nutrient removal from wastewater

- Selenium and other metals removal from wastewater

- Groundwater remediation

- Wastewater recovery

- Industrial water

- Emissions and odor control applications

- Life cycle cost solutions – performance warranties

Our technology-agnostic approach emphasizes value-engineering, enabling clients to make informed decisions, optimize resources, and enhance financial sustainability over their asset’s lifecycle.

We incorporate pilot plant trials to validate full-scale implementation, stress-testing processes to set operational limits and future-proof designs. This proven approach allows us to offer performance guarantees, significantly reducing risk, providing peace of mind, and ensuring reliable environmental management to meet both regulatory and budgetary goals.

Organics and Nutrient Removal from Wastewater

Effective removal of organic material (i.e., total organic carbon, volatile organic compounds) and nutrients, such as nitrogen and phosphorus, is essential to maintain water quality and prevent environmental contamination. Envirogen’s proprietary fluidized bed reactor (FBR) technology has been used to remove harmful organics and nitrogen from chemical production plant wastewater. The FBR has also been employed at Publicly Owned Treatment Works (POTWs) to remove nitrogen from wastewater before it is discharged. This technology can help municipalities meet strict nutrient removal mandates and enabled them to gain nutrient credits, which can be sold to other dischargers, offsetting treatment costs and creating additional revenue streams.

Envirogen also offers membrane bioreactor (MBR) systems and moving bed bioreactors (MBBR), which can be customized for specific applications, including landfill leachate treatment. For more stringent discharge requirements, the MBR system can be complemented by nanofiltration (NF), reverse osmosis (RO), or activated carbon (AC) treatment.

Additionally, we offer granular activated carbon (GAC) systems for organics treatment on both potable water and wastewater applications. We can also provide specialty absorbents for the treatment of specific contaminants.

Selenium and Other Metals Removal from Wastewater

Envirogen has the expertise and experience to effectively remove selenium and other metals from complex industrial wastewater streams, including flue gas desulfurization (FGD) effluent at coal-fired power plants, sour water stripper bottoms at refineries, and runoff water from strip-mining operations.

Our proven selenium treatment technologies include the biological fluidized bed reactor (FBR) and the advanced metals removal system (AMRS), which utilizes zero valent iron (ZVI) media. In addition, we offer systems utilizing specialty resins for a variety of applications, including chelating resins for the selective removal of specific metals, brine softening, and other substances. These solutions offer cost-effective compliance options, tailored to specific industrial requirements, and can be seamlessly integrated into broader water treatment processes. For further information:

- Selenium treatment for general industry, mining, power generation, agricultural, and groundwater applications.

- Specialized selenium treatment solutions for refineries, along with a fact sheet on our treatment experience.

Other metals:

In addition to selenium, our technologies are highly effective in removing other metals such as mercury, arsenic, chromium, iron, manganese, uranium, cobalt, molybdenum, and other regulated ions from industrial wastewater streams, ensuring regulatory compliance and environmental protection.

Groundwater Remediation

Municipal Remediation:

Envirogen specializes in the treatment of groundwater impacted by oxyanions and other contaminants, utilizing advanced, technologies to protect valuable water sources. We offer proven treatment approaches for a wide array of contaminants, including targeted solutions for nitrate, chromate, arsenic, and hexavalent chromium.

Industrial Remediation:

From an industrial contamination perspective, our extensive experience includes treating complex contaminants from munitions, solvents, and fuel production, such as:

- Explosives residue: RDX (Royal Demolition Explosive), HMX (High Melting Explosive), and perchlorate

- Nitrotoluenes: Including di-nitrotoluene (DNT) compounds.

- Rocket fuel contamination: Chlorate, perchlorate, and N-nitrosodimethylamine (NDMA).

- Chlorinated solvents: Including tetrachloroethylene (PCE), trichloroethylene, cis-1,2-dichloroethylene, chlorobenzene, and vinyl chloride.

- Toxic solvents: 1,4-Dioxane, dimethyl sulfoxide (DMSO), and tert-butyl alcohol (TBA).

- Gasoline and fuel contaminants: Including benzene, toluene, ethylbenzene, xylene (BTEX), methyl tert-butyl ether (MTBE), polycyclic aromatic hydrocarbons (PAHs), and some toxic metals.

Spotlight on Superfund Groundwater Remediation:

At the Nevada Environmental Response Trust (NERT) site, Envirogen built and operates the world’s largest groundwater treatment system for oxyanion contamination. This state-of-the-art facility in Henderson, Nevada, tackles persistent contaminants – including perchlorate, chlorate, nitrate, and hexavalent chromium – stemming from historic industrial activity. Our advanced treatment solution leverages a range of proprietary technologies, including the Fluidized Bed Reactor (FBR) to reduce contaminants significantly, ensuring compliance with stringent environmental standards and safeguarding downstream water sources, including the Las Vegas Wash, Lake Mead, and the Colorado River.

Envirogen FBR system, built and operational at NERT

Wastewater Recovery

Water conservation is essential for both municipal and industrial operations, where large volumes of water are used directly in production processes, as a component of the final product, or indirectly through energy consumption. By recapturing and recycling wastewater, industries can avoid discharge costs and reuse water for a variety of applications, including washing, rinsing, plating, cooling, boiler make-up, and fire suppression systems. The choice of method depends on the water’s quality, volume, and intended reuse, with factors like space and budget influencing the best approach.

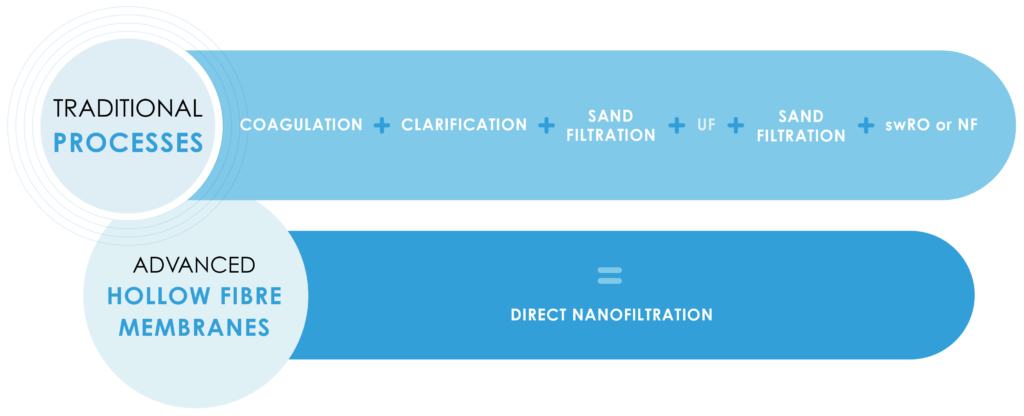

One effective solution is PureSep dNF (direct nanofiltration), an excellent choice for surface water treatment and waste stream recycling. PureSep dNF offers the rejection of dissolved solids with significantly less energy than comparable spiral-wound reverse osmosis processes. Each hollow fiber membrane in this system provides high fouling resistance with no need for pre-treatment, making it a highly efficient option for industries looking to recycle and reuse wastewater.

Read more in our article: Envirogen water recycling and reuse technology can help industry meet water usage goals.

By virtue of its solids handling capability and salt rejection properties, the PureSep NF

By virtue of its solids handling capability and salt rejection properties, the PureSep NFnanofiltration process can replace multiple stages simultaneously.

Industrial Water

Treating water to be safe for use in manufacturing is essential for maintaining product quality, protecting equipment, and ensuring compliance with environmental standards. Industrial processes like boiler feed, rinse water, product purification, and metals recovery all generate wastewater, which requires careful management to minimize discharge and maximize resource efficiency.

Envirogen offers tailored solutions for each of these applications, enabling industries to conserve water, reduce costs, and promote sustainable practices. To learn more about how we can support your industrial water needs, please contact us to discuss your specific requirements.

Emissions and Odor Control Applications

Emissions and odor control are essential components of effective wastewater treatment, as many treatment processes can release odorous and potentially harmful compounds that require specialized management. Controlling these emissions improves air quality and ensures compliance with environmental regulations, protecting nearby communities and ecosystems.

Envirogen is at the forefront of industrial and municipal emissions odor control with its biofilter and biotrickling filter technology, designed for the elimination of hydrogen sulfide (H2S), volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and reduced sulfur compounds (RSCs). With over 130 installations, these systems deliver high removal rates and offer numerous advantages over conventional and thermal odor control systems:

- Simple operation and maintenance

- Reduced chemical usage and storage

- Reduced energy usage

- Lower carbon footprint and overall emissions

Our biofilters and biotrickling filters are available as both modular and built-in-place systems, customizable to meet specific air flow rates and facility space requirements.

Biotrickling filter technology (municipal build in place system):

Clark County Water Reclamation District, Nevada,

Life Cycle Cost Solutions – Performance Warranties

As environmental regulations tighten and financial resources face increasing constraints, Envirogen provides cradle-to-grave, turnkey solutions designed to ensure safety and sustainability across both municipal and industrial applications. By integrating engineering and predesign, construction, comprehensive service, and ongoing operations support, we build enduring partnerships with a focus on lifecycle cost management, including both operational and capital expenditures (TOTEX).

Envirogen’s advanced solutions are built for efficient, long-term performance and are trusted worldwide. This includes the Nevada Environmental Response Trust (NERT) site, where we implemented a state-of-the-art groundwater treatment system that ranks the world’s largest treatment system for oxyanion contamination – demonstrating our commitment to reliability and environmental stewardship.

We establish long-term partnerships with our clients, enabling them to make informed decisions and optimize resources. Our solutions come with performance guarantees, providing reliable outcomes and peace of mind throughout the asset’s lifecycle.