Technology Options

Technology Options for Flue Gas Desulfurization Wastewater, Coal Ash Pond Waters & Combustion Residuals Leachate

With evolving federal regulations governing flue gas desulfurization (FGD) wastewater and coal combustion residuals (CCR), coal-fired power producers are challenged to stay competitive, and producers transitioning away from coal are now required to reclaim and safely decommission legacy CCR storage ponds. These regulations prohibit further CCR waste storage in surface impoundments, prioritizing timely treatment, dewatering, and remediation of these areas.

Envirogen brings extensive experience and a comprehensive technology suite to support efficient, compliant pond remediation and FGD wastewater treatment. Our solutions range from biological reduction and chemical precipitation to advanced ion exchange, nanofiltration, reverse osmosis, and zero-valent iron technology.

Envirogen has over 20 years of turnkey water and wastewater treatment design, installation, and operations and maintenance (O&M) experience, having successfully completed more than 100 industrial wastewater and groundwater remediation projects. Most of these projects included a requirement to remove toxic metals. Our experience has shown that the best treatment approach is often dictated by the specific water chemistry, including metals concentrations and forms, as well as the project’s duration – ensuring that your environmental goals are achieved with a cost-optimized, lifecycle-focused strategy:

Regulatory Drivers & Treatment Solutions

The Environmental Protection Agency (EPA) has set robust regulations to control toxic metal levels in wastewater from coal-fired power plants, with recent updates increasing standards even further.

Effluent Limitations Guideline (ELG) & Coal Combustion Residuals Rule (CCR)

The EPA’s ELG rule sets federal limits on the levels of toxic metals permissible in wastewater discharged from steam electric power plants, specifically targeting coal-fired operations. Additionally, the Disposal of Coal Combustion Residuals (CCR) from Electric Utilities and Independent Power Producers (CCR rule) aims to discourage CCR waste storage in surface ponds by motivating facilities to dewater and close these ponds.

EPA 2024 Updates to ELG & CCR

In May 2024, the Environmental Protection Agency (EPA) imposed more stringent standards on FGD wastewater, legacy wastewater, and combustion residuals leachate (CRL):

Groundwater Contamination Standards

- New limits on arsenic and mercury levels from unmanaged CRL affecting surface water bodies:

- Arsenic: 11 micrograms per litre max, 8 micrograms per litre monthly average.

- Mercury: 788 nanograms per litre max, 356 nanograms per litre monthly average.

- Envirogen’s Advanced Metals Removal System (AMRS) is designed to effectively eliminate these and other metals.

Mandating Zero Liquid Discharge (ZLD) – Sustainability Goals

- The EPA mandates ZLD as the best available technology (BAT) economically achievable for managing flue-gas desulfurization (FGD) wastewater and CRL at coal-fired power plants using coal beyond 2034.

- This mandate ensures zero discharge of contaminated water into the environment from these facilities, providing the highest level of protection for waterways, groundwater, and ecosystems from harmful substances such as mercury, selenium, and arsenic.

- Membrane-based ZLD approaches, including reverse osmosis (RO), ultrafiltration (UF), and direct nanofiltration (dNF) technology, facilitate water reuse initiatives and align with the EPA’s sustainability goals.

- Envirogen’s ZLD-optimized membrane solutions significantly reduce the volume of brine needing evaporation or immobilization, improving treatment efficiency and compliance.

Amid increasing regulations and heightened local environmental concerns over coal combustion residual management, it’s crucial for coal-fired facilities to adopt treatment options for CRL that are not only efficient but also sustainable. The expansion of the CCR rule to include legacy CCR impoundments and CCR management units underscores the urgent need for innovative treatment solutions that can effectively address these environmental challenges.

Groundwater Contamination from Legacy Wastewater & Combustion Residuals Leachate

Groundwater Extraction and Treatment

For sites where groundwater may be impacted by Combustion Residuals Leachate (CRL), Envirogen offers groundwater extraction and treatment systems designed for hydraulic control, removal of arsenic and other metals, O&M services, and groundwater monitoring. Envirogen has extensive experience in treating selenium, arsenic, mercury, chromium, lead, thallium, iron, manganese, aluminum, vanadium, cadmium, copper, and other metals. For more details, visit our Groundwater Remediation page.

Advanced Metals Removal System with FerroLock Zero Valent Iron

Envirogen offers a solution for meeting arsenic, mercury, and other metal discharge requirements associated with legacy wastewater and Coal Combustion Residuals Leachate (CRL). Our Advanced Metals Removal System (AMRS), featuring FerroLock Zero Valent Iron (ZVI) media can be configured as standalone columns or containerized units, adapting to different ZVI media sizes and densities for optimal performance.

Extensive research and testing of different iron-based media formulations have been completed to help us select the optimum ZVI media for each water chemistry, resulting in the development of our high-efficiency FerroLock ZVI media.

- For more details and a full technology overview, visit our AMRS and ZVI webpage.

- Learn more about Envirogen’s evaluation of Zero Valent Iron (ZVI) and other iron-based media.

An Envirogen field-based pilot and full scale AMRS system utilizing FerroLock ZVI media

Membrane-Based Zero Liquid Discharge (Water Re-Use)

Envirogen’s membrane-based ZLD approaches, including reverse osmosis, innovative hollow fiber membrane ultrafiltration, and direct nanofiltration technologies, facilitate water reuse initiatives and play a vital role in optimizing water recovery while reducing reliance on external water sources. Notably, our ZLD-optimized membrane solutions significantly reduce the volume of brine requiring evaporation or immobilization, improving treatment efficiency and ensuring compliance.

Hollow Fiber Membranes

Envirogen hollow fiber membrane systems offer significant savings in energy and chemical consumption compared to traditional membrane technologies. We provide comprehensive testing options, including lab-scale bench-top and skid-based UF/NF membrane pilot plant trials for on-site testing and evaluation:

- PureSep Ultrafiltration (UF): Developed for the power market, PureSep UF membrane technology enhances filtration capabilities, making it ideal for RO pre-treatment. These UF membranes excel in removing suspended solids, bacteria, and viruses.

Compact PureSep UF skid with innovative hollow fiber membranes: We also offer mobile ultrafiltration and nanofiltration Skid systems, available for on-site pilot plant trials and testing.

- PureSep Nanofiltration (NF): Designed for partial dissolved solids removal from ground and surface waters containing suspended solids. PureSep NF membranes provide rejection of dissolved solids while consuming a fraction of the energy required by traditional and comparable spiral wound NF processes.

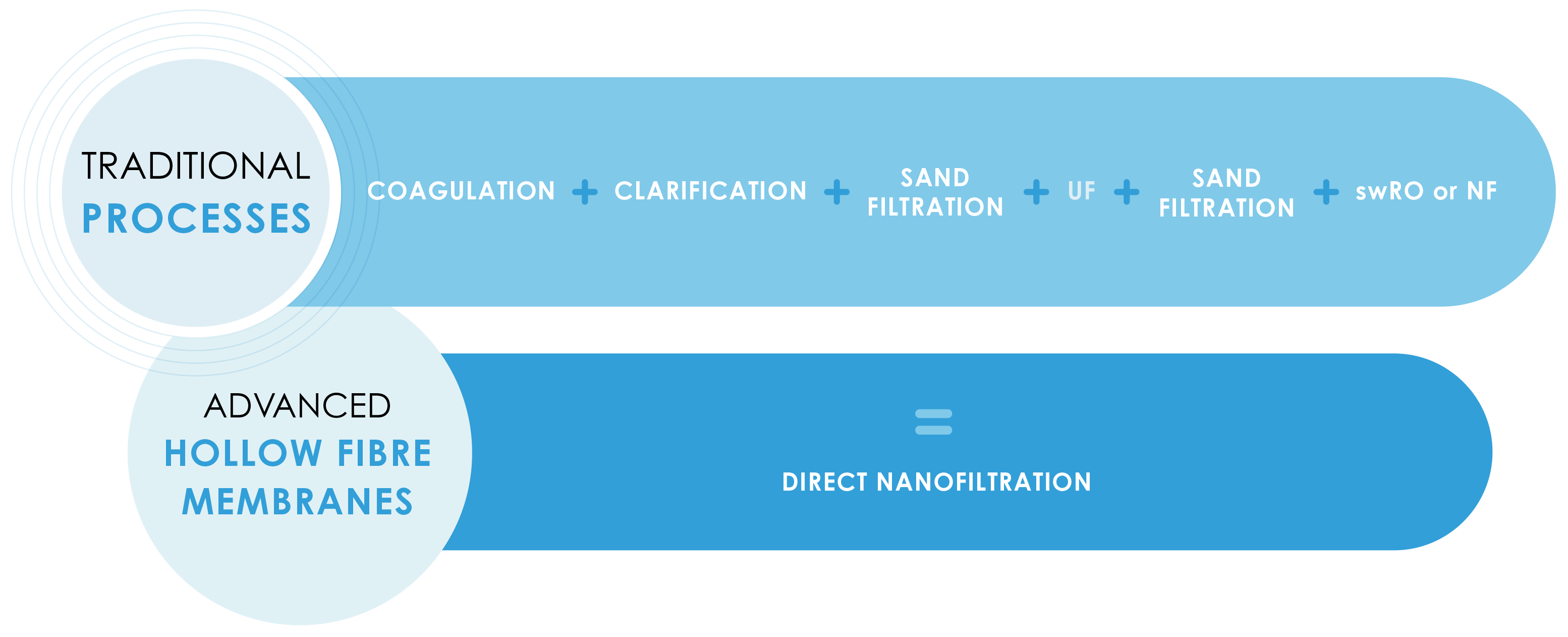

By virtue of its solids handling capability and salt rejection properties, the PureSep NF

nanofiltration process can replace multiple stages simultaneously.

Reverse Osmosis

Envirogen’s modular, skid-based reverse osmosis (RO) systems are specifically optimized for power plants, designed to deliver consistent high-purity water, which enhances equipment efficiency and lifespan. These systems are adaptable to both large and variable flow conditions, ensuring reliable operation:

- Eco MultiPro RO-EDI: Our skid-mounted RO and EDI (electrodeionization) system combines high efficiency with a compact design. It provides continuous, chemical-free ultra-pure water and features low-energy RO membranes that achieve up to 98% water recovery, enhancing flow rates and reducing operating costs.

- Custom-built solutions: Envirogen can custom design and build an RO solution that is specifically tailored to meet your unique site requirements, ensuring seamless integration and optimal performance.

Life Cycle Cost Solutions – Performance Warranties

As environmental regulations tighten and financial resources become more constrained, Envirogen offers innovative solutions that ensure safety, reliability, compliance, and sustainability for power plant water treatment applications. Combining advanced technology, equipment expertise, and operational experience, Envirogen delivers efficient water and wastewater treatment systems, proven at hundreds of sites worldwide.

We build long-term partnerships with a focus on lifecycle cost management, helping clients optimize resources and make informed decisions. Our solutions come with performance guarantees, ensuring reliable outcomes and peace of mind throughout the asset’s lifecycle.